how to do a rockwell hardness test|mohs scale of hardness chart : inc Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as . Resultado da 24 de nov. de 2021 · Foto: Reprodução / Portal do Zacarias. Na manhã da última segunda-feira, 22/11, por volta das 8 horas, José da Costa Gonçalves de 57 anos, estava trafegando com uma bicicleta quando morreu após ser atropelado por um ônibus, na Avenida Comendador Luciano Guidotti, em .

{plog:ftitle_list}

HBB Hostel - Vila Madalena asub São Paulos, kus on mitme.

Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as . The Rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the Rockwell formula. The resulting value is then translated to .TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .

rockwell hardness testing chart

rockwell hardness tester diagram

The Rockwell hardness test is a measuring system used to determine how resistant a material is to another object. Grab this complete guide.The Rockwell Hardness Test uses a diamond cone or hardened steel ball to indent the material being tested. Each time a test is performed, two loads are applied to the sample. First, the indenter is forced into the test material under . Tutorial video on how to use rockwell hardness tester.For Scale B Tests.

Basic principle and practical procedure of the Rockwell hardness test - Testing machine, test piece, conical diamond indenter - Basic principle, hardness d.

Principle of Test. The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test .What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared .

Tensile Strength Tester manufacturing

rockwell hardness test theory

Tensile Strength Tester factory

The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on surfaces with moderate roughness, making it a practical choice for a wide range of materials and surface conditions.Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion . Verification should be performed by an accredited verifying agency and the report should follow and reference ASTM E18 Rockwell test method. Hardness testing is an important and useful tool in materials testing, quality control and acceptance, and performance of materials. We depend on the data produced to verify heat treatment, structural .Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .

Minimum Thicknesses for the Rockwell Hardness Test. Since the Rockwell test needs to make an indent in the test piece, there’s a minimum thickness associated with the test. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. Here’s a little chart on the minimum material .

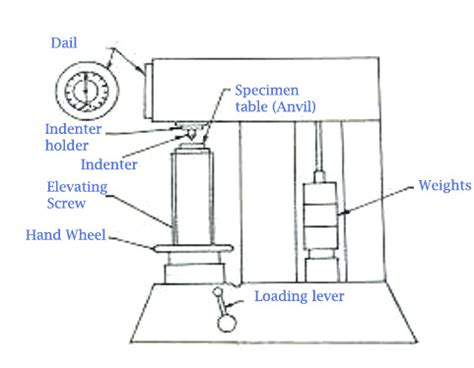

Rockwell Hardness Test. The Rockwell hardness test evaluates the hardness of a material by measuring the permanent depth of indentation due to an applied concentrated load. The higher the number on the Rockwell hardness scale, the harder the material. The test is conducted by applying a minor force of 10 Kg using a diamond cone or a steel ball .The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject. First, an indenter is forced into the test subject under an initial load of 10kg-f, and the depth is recorded. In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm serves as the indenter. The indentation depth can be read directly from a dial gauge via the traverse path of the testing machine.

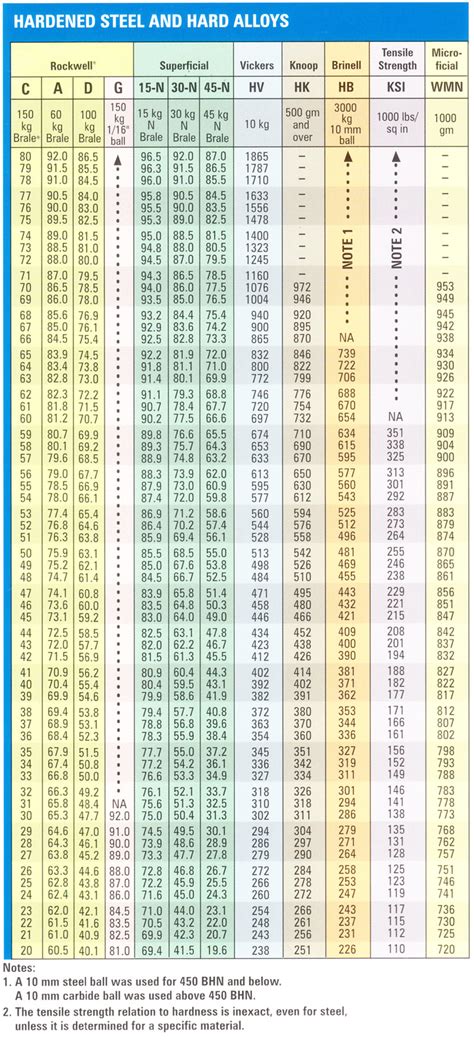

The concept of the Rockwell Hardness test is essentially similar to its counterparts. A sample material is fed on to either a digital or manual Rockwell hardness tester which would then drop a set load ending with an indenter on the surface. Then, the strength of the material will be determined by the nature of the indentation left on the sample.See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .For instance, converting from a Rockwell hardness test on the C scale (HRC) to a Brinell hardness test value requires using the formula: BHN = 5.970 x (HRC + 104.7). This formula gives an approximate value for the Brinell hardness value, and quality assessment professionals use it to create the conversion tables and charts for instant conversion.

rockwell hardness test pdf

Many Rockwell test standards also stated that while processing the test, there should be a distance of more than 2.5 times the diameter of the indentation between mid of an indentation and the periphery of the material. Thickness of Test Material In the Rockwell hardness test, indentation depth depends on the thickness of the material.

Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: HRC – Known as “Rockwell C,” a 150 kgf load is applied via .

Advantages of Rockwell Hardness Test. Typically, the Rockwell test is easy to execute and more precise than other kinds of hardness evaluations. The Rockwell test technique is used on all metals, except when .

Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, .The Rockwell hardness test involves indenting the surface of a material with a diamond cone or steel ball indenter and measuring the depth of the resulting indentation. Significance of Rockwell Hardness. Rockwell hardness is significant because it is a quick and easy method of measuring the hardness of a material. It is also a reliable method .The Rockwell hardness test. Rockwell is a fast hardness test method developed for production control, with a direct readout, mainly used for metallic materials. The Rockwell hardness (HR) is calculated by measuring the depth of an indent after an indenter has been forced into the specimen material at a given load.

The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. This test was created to determine the hardness and strength of materials. After executing the Rockwell hardness test, you will be able . Rockwell hardness testing can determine the hardness of most metals, alloys and plastics, ranging from the softest bearing materials to the hardest steels. Photo: Wilson Instruments, An Instron Company. Stanley P. Rockwell invented the Rockwell hardness test. As a metallurgist for a large ball bearing company, he wanted a fast, nondestructive .

Hardness is a primary concern when deciding which building materials to use for construction. Performing hardness testing can take many forms, depending on the protocols followed. There are many hardness scales and one of the most common is the Rockwell scale. To convert Rockwell Hardness to Tensile Strength, use a .

Tensile Strength Tester factories

🕑 Reading time: 1 minute Hardness of a material is defined as its resistance to indentation. Rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness scale is designed to determine the [.] The calculator has two modes — calculate and convert.The calculate mode is helpful if you have the indentation depth and want the Rockwell hardness number for either scale B or C. The convert mode is for converting Rockwell hardness numbers to a different scale like Brinell or Vickers.. The hardness data can not be presented in terms of a universal .

Rockwell Hardness Testing. Because of its low force, high speed, and nondestructive nature, Rockwell hardness testing commonly is used on all sizes of tubing. To perform a Rockwell test successfully, you must consider several factors. Surface Finish. The surface finish for Rockwell testing must be smooth and uniform to obtain an accurate .

3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .

20 de abr. de 2023 · Siga o PORTAL DO ZACARIAS no Facebook, Twitter e no Instagram. Entre no nosso Grupo de WhatApp e Telegram . VEJA VÍDEOS: . o melhor comentário é o seu. Não tem nem que perder tempo. Assim talvez a vida fosse um pouco mais valorizada, pois os vagabundos iam pelo menos pensar duas vezes antes de matar alguém. .

how to do a rockwell hardness test|mohs scale of hardness chart